After a ridiculously great ski season, sailing season is upon us once more. Before a planned May trip out to the islands it was time for a few days of good old fashioned dirty work. As is often the case, the big projects largely revolved around, well, power:

SOLAR POWER

Last year we mounted 100 watts of solar on our Sportsmobile camper van and have really enjoyed having that extra juice… less worry about how hard the fridge is running when it’s hot, and less need to run a generator if we camp in one spot for multiple days. So if 100 watts was good in the van, 200 should be great in the boat, right? We ran some of the numbers, and while more is always better, 200w seemed a good compromise between our existing power draws (mostly our Engel fridge, the Wallas furnace, and our old school incandescent anchor light when we’re not at the dock) and space to mount the panels.

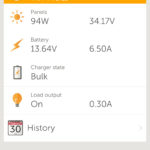

Unlike many boats that have a large stern pulpit, and boarding gates in the middle of the boat’s lifelines, access on and off Boundary happens straight from the cockpit and any large panel mounted on the pulpit was going to interfere with boarding and disembarking. The solution we came up with was to create our own folding solar setup: basically, instead of buying one 100w panel for each side we bought two 50w panels for each side, mated them together with an aluminum piano hinge and mounted them to the pulpit. The added bonus here was each pair of 50w panels is wired in series, giving independent 24 volt systems on each side which should work well with our Victron MPPT controller (designed to work most effectively with higher voltage systems). A nice feature of the Victron controller is no need for a separate display mounted somewhere, you can buy the add on Bluetooth dongle and see all the data about your system on your phone or tablet… pretty slick.

Mounting was accomplished with Marinco clamps that allow for pivoting of the panels (although they only pivot toward the outboard side of the boat, they can’t pivot inboard because of the back stays in the way) and Marinco trolling motor plugs through the stern locker.

MUSCLE POWER

Gulf 32’s (or at least ours) aren’t shy for winches… there are a total of 6 on this boat: two on the mast (jib and main), two on the cabin top (main sheet and, we’re guessing, main traveler) and two jib sheet winches. All seem original and are in decent shape, but they’re all non-self-tailers… really not an issue with the other four winches but we sure wished for self tailers for the jib sheets; with self tailing jib sheet winches it means not having to take the sheet off the winch every time you trim, and makes our most frequently used winches overall more convenient so you don’t have to worry about tailing it yourself (not always easy when we primarily double hand this boat… Hobie seems none too adept at tailing a sheet!). When Minney’s Yacht Surplus in Costa Mesa advertised a killer deal on Lewmar Evo 30ST’s we jumped at the chance, and then right before pulling the trigger figured, why not go one size larger as well… so we ended up with a pair of brand new Lewmar Evo 40ST’s… the 40’s will give a little more power (larger drum) for when the wind pipes up.

Winch mounting was going to be challenging and time consuming (lots of waiting for epoxy to dry etc) though, and it took almost a year before we had the chance to do the swap. First step was cutting a (gulp) 6″ hole in our cockpit coaming… yep, boat came from the factory with no way to access the bottom of the starboard winch, so it was either cut a hole in the coaming or one in the top of the quarterberth. Without a headliner to worry about, coaming seemed way to go. Then it was loosen the old bolts (which required crawling all the way into the port side cockpit locker to access THOSE bolts… felt like George Costanza napping under his desk in Seinfeld!), remove the old winches, fill the old holes with thickened epoxy, drill new oversized holes for the new winch bolt pattern, fill THOSE with epoxy, redrill to size, taper the holes, bed with butyl tape and mount the new winches… with a desperate search for very obscure 6mm machine screws thrown in (after much driving and consternation, realized that a very standard 1/4″ machine screw would work just fine, and in fact discovered the original winches had been mounted with just that screw!). All while only losing one little (replaceable, thank goodness) part over the side! And in the interests of good boat gear karma, a good home was found for the older but still very functional 30’s.

“ROBOT” POWER

A smaller project was getting the existing wheel pilot sorted out. When we bought the boat the broker told us that it had a “working autopilot” but he couldn’t produce it at the time of sale so we discounted its existence from the price. But there were hints around that it existed… random wires in the steering binnacle under the compass, an obvious wheel drive powered unit mounted to the cockpit wheel, and (when we went through the boat after purchase) a Raymarine ST4000+ control head. During some previous wiring work of the depth and speed displays we also found a mounted fluxgate compass in the interior steering binnacle. Some research showed that, in theory, we had everything we needed, it just needed to be wired all back together.

Some pulling of wires and creation of a new instrument mounting board and we now have what appears to be a working Raymarine ST4000+ wheel pilot (for those not familiar, a wheel pilot is a lighter duty, less hardcore style of autopilot which steers by simply steering your wheel for you, as opposed to a heavier duty autopilot that steers by turning the rudder shaft itself).

There were some hiccups, which I’ll include here in case anyone’s ever researching this. For one, we were supposed to have five wires from the compass to the control head (according to the manual, the colors were red, blue, yellow, green, and “screen”) but we only found four (red/blue/yellow/green), leaving us perplexed and wondering what color “screen” was anyway. After cutting the sheathed wires back a ways we found a fifth, uninsulated wire… after some CruisersForum and Raymarine support forum querying we established this was, in fact, the “screen” wire and should have a connector crimped to it and plugged into the control head. Other, err, hiccup was that Bass has a lot to learn about varnishing… despite 5 coats of varnish on the new board (generously provided by Bailet’s Boat Shop in Bellevue from leftover mahogany floor sample) it wasn’t allowed to dry long enough before being wrapped up for transit, so the bubble wrap left large marks in the board… DOH! It has come back to Idaho with us for a little more tuning up.

ENGINE POWER

Final (and more or less most dreaded) project was improving the cooling of various parts of our mechanical genny (i.e., the engine). After our trip last fall we did an oil analysis on engine oil and transmission fluid, and the report on the tranny fluid (a very small quantity, barely 1/2 liter, of ATF fluid) came back as oxidized, which is most likely a sign that the fluid has been getting hotter than we’d like. To try to “cure” that, or at least make it less likely, we installed a transmission oil cooler. Unfortunately we couldn’t source a true transmission cooler for our venerable Hurth HBW100-2R so our only real option was more of a “heat sink”, basically an aluminum block that bolts to the transmission that we run raw water through. This involved splicing into the existing raw water cooling circuit to run raw water down through the cooler before it goes to the heat exchanger. Concerned about the possibility of failure of this circuit (aluminum and saltwater don’t love each other, although we will from now on be flushing the raw water system with fresh water before leaving the boat for extended periods), we built a manifold of Groco parts that can run all the raw water through the cooler, only some, or none at all, so if something fails in the part of the raw water circuit that goes to the transmission cooler that whole circuit can be shut all the way off.

While we were at it we also added a third Engine Watchdog temperature sensor (this time the TM1) to monitor transmission temperature directly… for more info on these nifty gadgets see our previous post “Some Like it Hot”

While we were at it we also changed out the older looking fresh water heater hoses that go between the engine and the heat exchanger. Bass had ordered new 3/4″ ID hose (because that’s what the old hose was) but painfully discovered that, short of buying really crappy 3/4″ hose and heating the heck out of it, there was no way 3/4″ ID hose was going into this system. Research showed that this was supposed to be 7/8″ hose anyway, so after some calling around and driving around we sourced some 7/8″ ID hose at O’Reilly’s and were in business… would have preferred to use more marine style (burly) hose, but at least this is on the fresh water circuit not raw water / below the waterline side.

For anyone (still reading) interested in what products / parts were used for these projects:

SOLAR:

– Renogy 50w monocrystalline panels

– Minn Kota MKR 18 trolling motor plugs

– Marinco mounting clamps

– Victron 75/100 MPPT controller

– Victron Bluetooth dongle

WINCHES:

– Lewmar EVO 40ST

– Bedit Butyl Tape

TRANSMISSION COOLER:

– Hurth / ZF transmission cooler

– Engine Watchdog TM1 temperature gauge

RAW WATER FLOW TO TRANSMISSION COOLER:

– Shields 160 and 200 hose

– Groco PTH-1125 1-1/4NPT to 1-1/8ID

– Anderson 83119-2008 Bell Reducer 1-1/4 – 1/2

– Groco PTH-5062 1/2″-5/8″ ID 1/2″NPT

– Groco PTHC-5062 1/2″-5/8″ to 1/2″NPT elbow

– Groco PN-500 1/2NPT to 1/2NPT

– Midland 44-253 1/2″ NPT Tee

– Groco Bronze Ball Valve

– Various AWAB hose clamps

Oy! Such work. Anyone else see the irony in using solar power on a sailboat? Wind power I can understand!

Hoping it’s a great season for you,

xoDebbie

I also am the proud owner of a Gulf32. A dream boat some 40years in the making. Many upgrades and improvements (not needed, but desired). I enjoyed your read and would be very happy to share Maid Marion ll experiences with you as well. FYI; that extra winch on the cabin top, is for your stay-sail…….I am cutter rigged and wish I had that extra winch. However, do have dual sheet fair leads. Stay in touch, sail well CLK

I simply cannot believe what was accomplished in a couple ofdays. I didn’t understand anything but read carefully anyway. These improvements should make the next sailing season very sweet. Sana